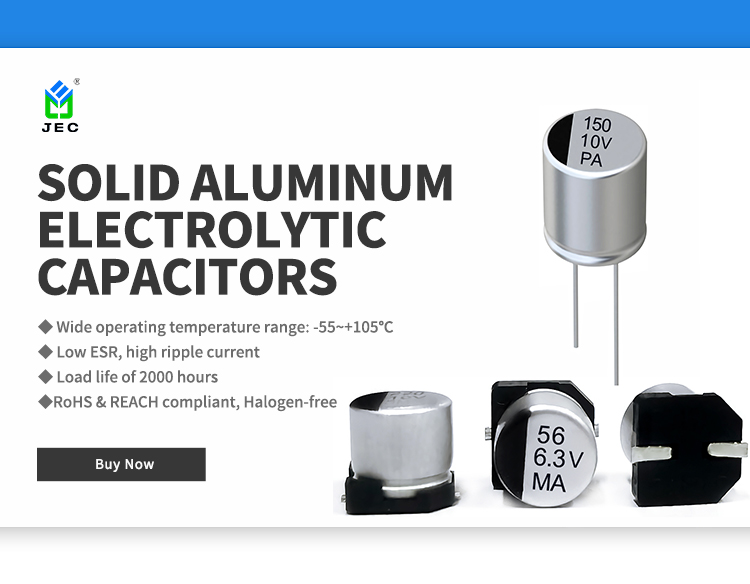

Electrolytic Capacitor High Frequency 10uf 25V

Features

Wide operating temperature range: -55~+105℃

Low ESR, high ripple current

Load life of 2000 hours

RoHS & REACH compliant, Halogen-free

Application

Due to the advantages of high frequency resistance, high temperature resistance, high current resistance, etc. In addition, the solid electrolytic capacitor itself is not easily affected by the surrounding temperature and humidity. It is suitable for low voltage and high current applications, mainly used in digital products such as thin DVD, Projectors and industrial computers, etc.

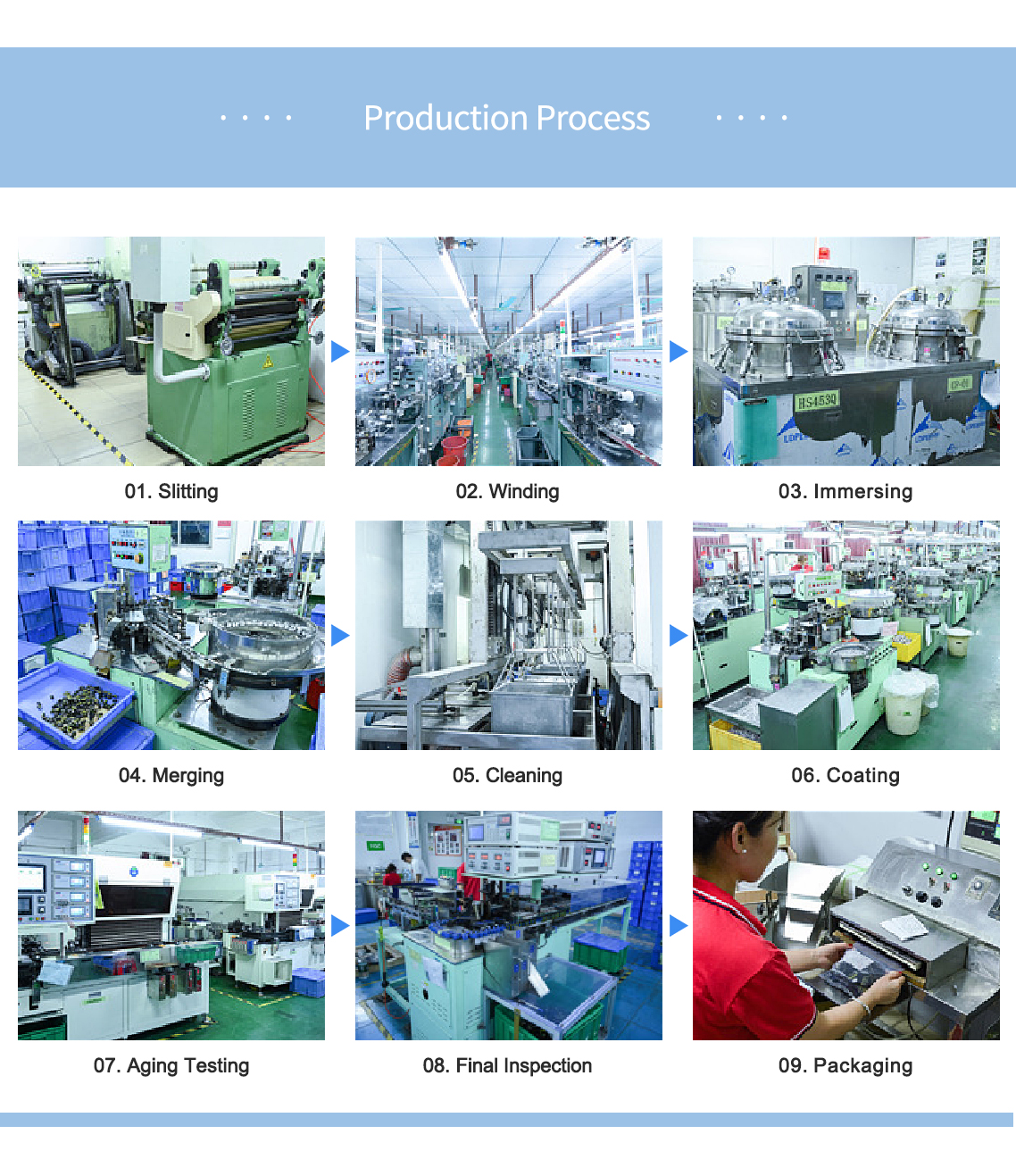

Production Process

FAQ

Q: How to distinguish between liquid aluminum electrolytic capacitors and solid capacitors?

A: A very simple way to distinguish solid capacitors from electrolytic capacitors is to see if there is a "K" or "+"-shaped slot on the top of the capacitor. Solid capacitors do not have slots, while electrolytic capacitors have open slots on the top to prevent explosion due to expansion after being heated. Compared with the common liquid aluminum capacitors commonly used at present, the physical difference of solid aluminum electrolytic capacitors is that the conductive polymer dielectric materials used are solid rather than liquid. It will not cause explosion when it is turned on or powered on like ordinary liquid aluminum capacitors.

What precautions should be taken when using electrolytic capacitors?

1. Check that there are no pads and vias on the front and back of the electrolytic capacitor.

2. Electrolytic capacitors should not be in direct contact with heating elements.

3. Aluminum electrolytic capacitors are divided into positive and negative poles. Reverse voltage and AC voltage cannot be applied. If reverse voltage occurs, non-polar capacitors can be used.

4. For places that need rapid charge and discharge, capacitors with longer life should be used, and aluminum electrolytic capacitors should not be used.

5. Excessive voltage cannot be used.