MLCC Multilayer Capacitor Manufacturers

Features

Using advanced process technology to create thinner ceramic dielectric layers can provide higher capacitance while improving withstand voltage capability. JEC MLCCs have good frequency response and high reliability.

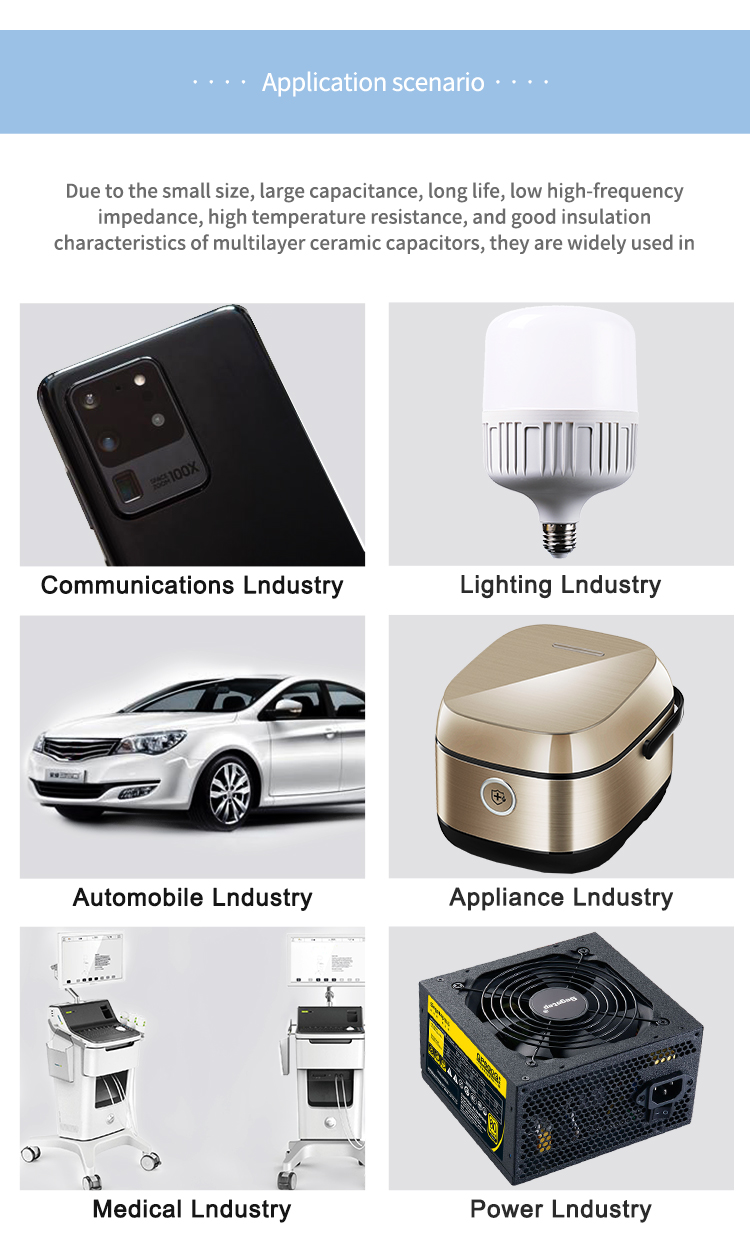

Application

Computers, air conditioners, refrigerators, washing machines, microwave ovens, printers, fax machines, etc.

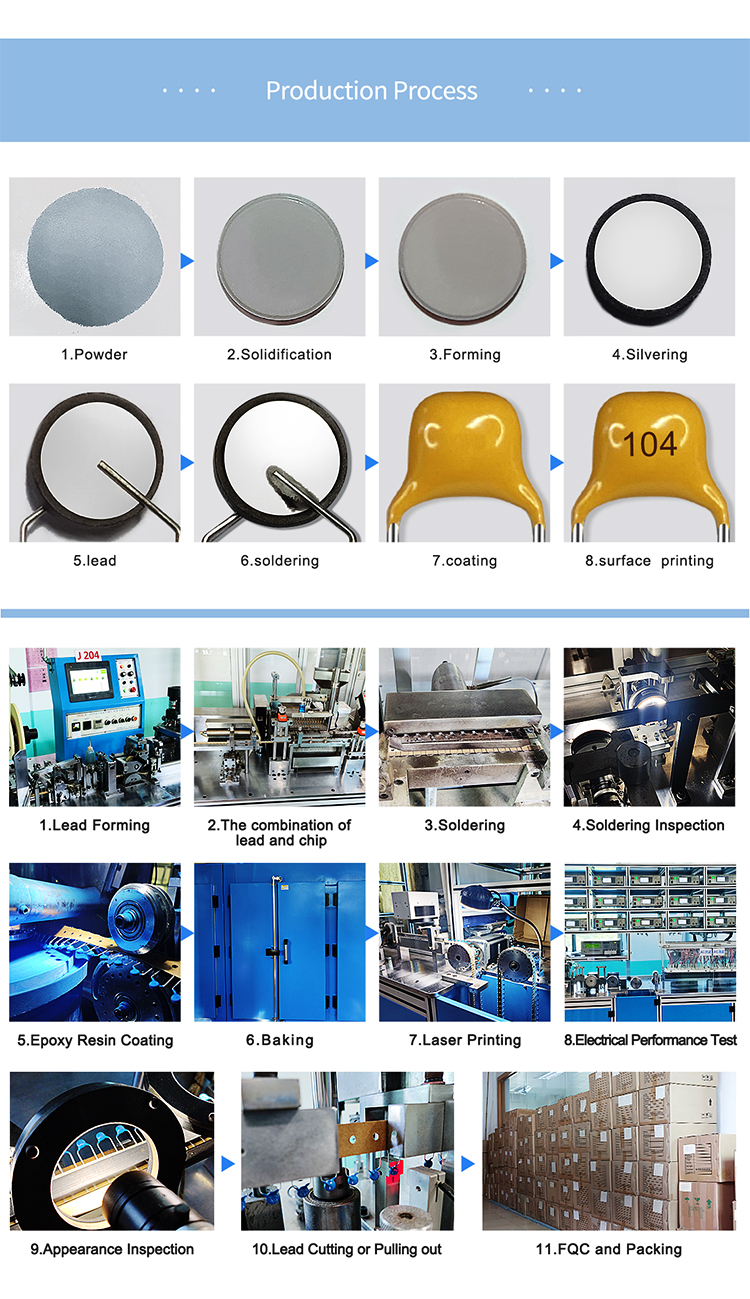

Production Process

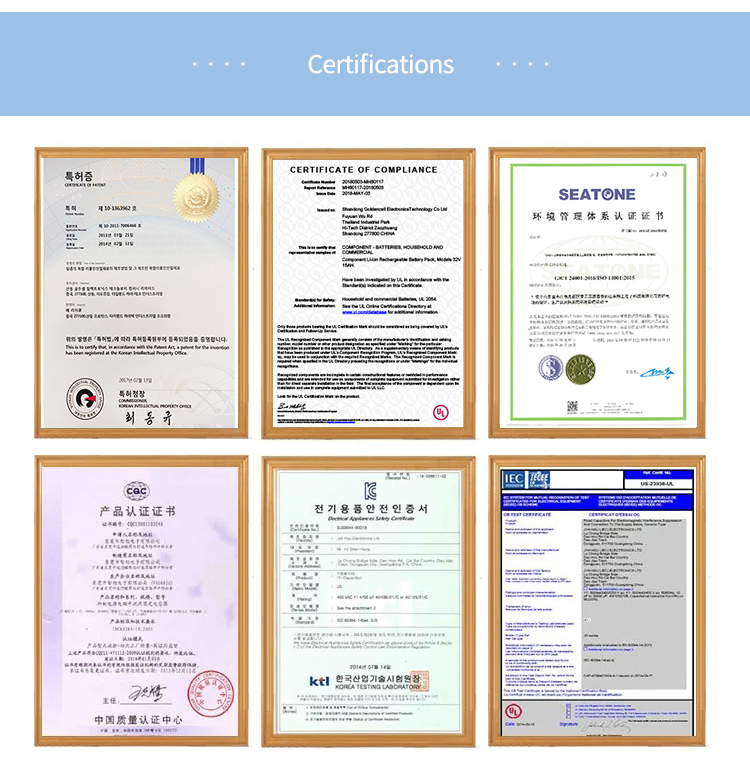

Certification

FAQ

Q: What is the cause of leakage of multilayer ceramic capacitors?

A: Internal factors

Void

The void formed by the volatilization of foreign matter inside the capacitor during the sintering process. Voids can lead to short circuits between electrodes and potential electrical failure. Larger voids not only reduce the IR, but also reduce the effective capacitance. When the power is turned on, it may cause local heating of the void due to leakage, reduce the insulation performance of the ceramic medium, aggravate the leakage, and cause cracking, explosion, combustion and other phenomena.

Sintering Crack

Sintering cracks are generally caused by rapid cooling during the sintering process and appear in the vertical direction of the electrode edge.

Layered Delamination

The occurrence of delamination is often caused by poor lamination or insufficient debinding and sintering after stacking. Air is mixed between layers, and jagged lateral cracks appear from external impurities. It may also be caused by a mismatch in thermal expansion after mixing different materials.

External Factors

Thermal Shock

Thermal shock mainly occurs during wave soldering, and the temperature changes sharply, resulting in cracks between the internal electrodes of the capacitor. Generally, it needs to be found through measurement and observed after grinding. Usually, small cracks need to be confirmed with a magnifying glass. In rare cases, there will be cracks visible to the naked eye.