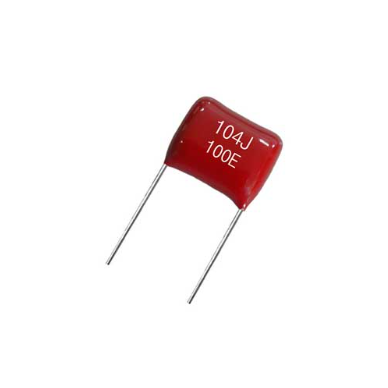

Film capacitors utilize metal foil as electrodes and employ plastic films like polyethylene, polypropylene, polystyrene, or polycarbonate as the dielectric material. They come in various types based on the specific plastic film used, such as polyethylene capacitors (Mylar capacitors), polypropylene capacitors (PP capacitors), polystyrene capacitors (PS capacitors), and polycarbonate capacitors.

One distinctive feature of film capacitors is their self-healing properties, categorized into discharge self-healing and electrochemical self-healing. This unique attribute allows film capacitors to recover from damage without requiring replacement, thereby reducing maintenance costs and troubleshooting time significantly.

Despite this advantageous self-healing capability, users should be mindful of a crucial factor: the gradual reduction in capacitance over time. With each instance of self-healing, the film capacitor’s capacitance and insulation resistance decrease, leading to a notable increase in the loss angle and a quicker onset of capacitor failure. Consequently, it is imperative to deploy film capacitors judiciously to prevent triggering their self-healing property unnecessarily.

When procuring film capacitors, it is essential to select a reputable manufacturer. We are JYH HSU (JEC) Electronics Ltd (or Dongguan Zhixu Electronic Co., Ltd.), an ISO 9000 and ISO 14000 certified electronic components manufacturer. Should you have technical inquiries or require samples, please do not hesitate to reach out to us.

Post time: Jan-29-2024