Film capacitors refer to capacitors that use metal foil as electrodes, and plastic films such as polyethylene, polypropylene, polystyrene, or polycarbonate as dielectric. Film capacitors are well known for their high insulation resistance, good heat resistance and self-healing properties.

Why we often emphasize that we should pay attention to the environment when using film capacitors? Because unsuitable environment will shorten the service life of film capacitors directly.

①Harsh Environment

In an environment that is in direct contact with water, salt water, oil or dew, an environment full of harmful gases (sulfide, ammonia, etc.), direct sunlight, ozone, ultraviolet rays and radioactive substances, vibration and shock conditions the service life of film capacitors will be decreased.

②Overcurrent

Before using it, you need to know the ripple current that the film capacitor can withstand. Because when a ripple current exceeding the rated value is applied to the film capacitor, the film capacitor body will be overheated and the capacitance will decrease, thereby shortening the service life.

③Voltage

If the voltage in the circuit exceeds the rated voltage of the film capacitor, when the voltage applied to the capacitor is higher than the rated working voltage, the leakage current of the film capacitor will increase, and its electrical and oxygen properties will deteriorate to damage in a short period of time. It should also be noted that there are many inferior film capacitors on the market today. For example, a film capacitor with a print of 250V may be printed as 400V, which will also lead to a worse withstand voltage of the capacitor, so you should be careful to test the film capacitor before purchasing them in bulk.

④Temperature

Many film capacitors may be used in power circuits or in harsh outdoor environments. Make sure that the operating temperature of film capacitors does not exceed the temperature in the manufacturer’s specification, otherwise the service life of the film capacitor will also be affected.

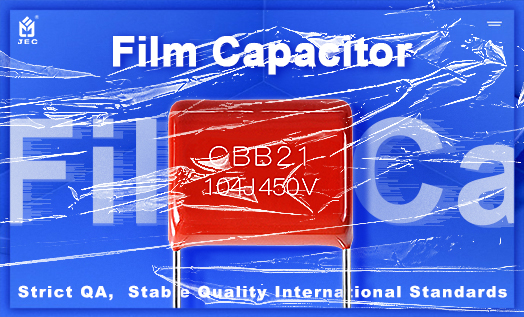

JYH HSU(JEC) Electronics Ltd (or Dongguan Zhixu Electronic Co., Ltd.) is the original manufacturer of various kinds of electronic components. JEC has passed ISO9001:2015 quality management system certification; JEC safety capacitors (X capacitors and Y capacitors) and varistors have passed national certifications of the main industrial powers across the world; JEC ceramic capacitors, film capacitors and super capacitors are in compliance with environmental protection indicators.

We have over 30 years of manufacturing experience. If you have technical questions or need samples, please contact.

Post time: Sep-23-2022