Safety Ceramic Capacitor Y1 Type/ Safety Ceramic Capacitor Y2 Type

|

Technical requirements reference Standard |

IEC 60384-14 ; EN 60384-14 ; IEC UL60384 ; K 60384 |

|

Certification mark |

VDE / ENEC / IEC / UL / CSA / KC / CQC |

|

Class ; Rated Voltage(UR) |

X1 / Y1/Y2 ; 400VAC / 300VAC/500VAC |

|

Capacitance Range |

10pF to 10000pF |

|

Withstand voltage |

4000VAC for 1min/2000VAC for 1min/1800VAC for 1min |

|

Capacitance Tolerance |

Y5P±10%(K ) ; Y5U,Y5V±20%(M) measured at 25℃,1Vrms,1KHz |

|

Dissipation Factor (tgδ) |

Y5P,Y5U tgδ≤2.5% ; Y5V tgδ≤5% measured at 25℃,1Vrms,1KHz |

|

Insulation Resistance(IR) |

IR≥10000MΩ,1min,100VDC |

|

Operating Temperature |

-40℃ to +85℃ ; -40℃ to +125℃ |

|

Temperature Characteristic |

Y5P,Y5U,Y5V |

| Flame Retardant Epoxy Resin |

UL94-V0 |

Application Scenario

Charger

LED lights

Kettle

Rice cooker

Induction cooker

Power supply

Sweeper

Washing machine

• Transistor, Diode, IC, Thyristor or Triac semiconductor protection.

• Surge protection in consumer electronics.

• Surge protection in industrial electronics.

• Surge protection in electronic home appliances, gas and petroleum appliances.

• Relay and electromagnetic valve surge absorption.

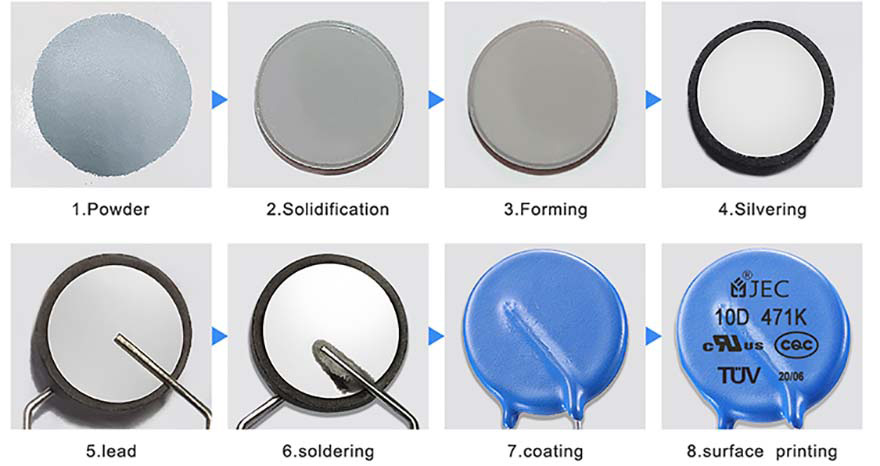

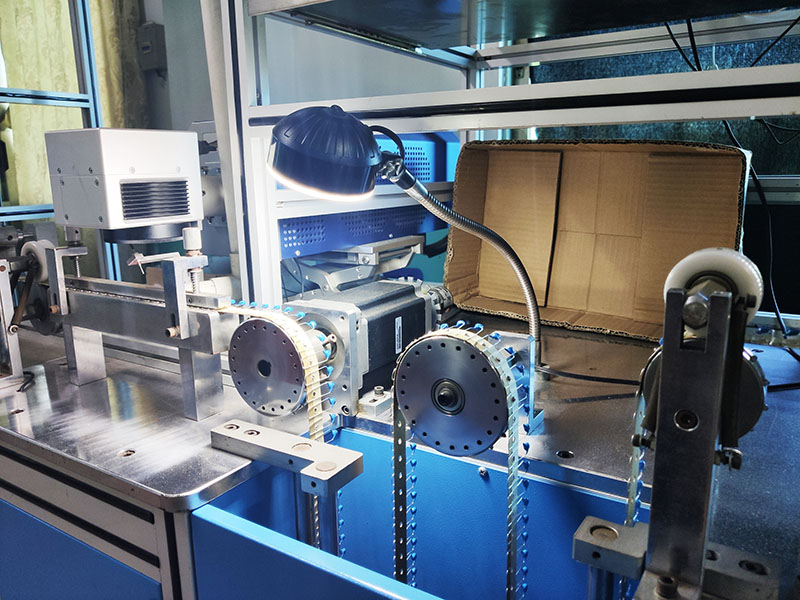

Production Process

1. Lead Forming

2. The Combination of Lead and Chip

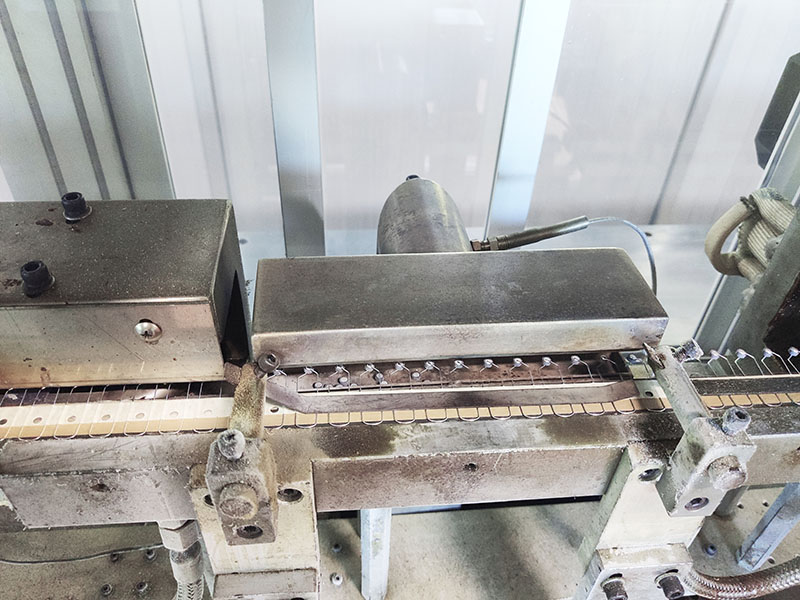

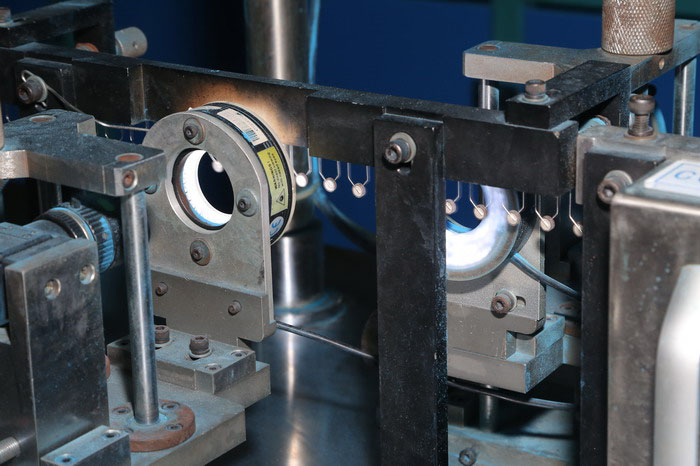

3. Soldering

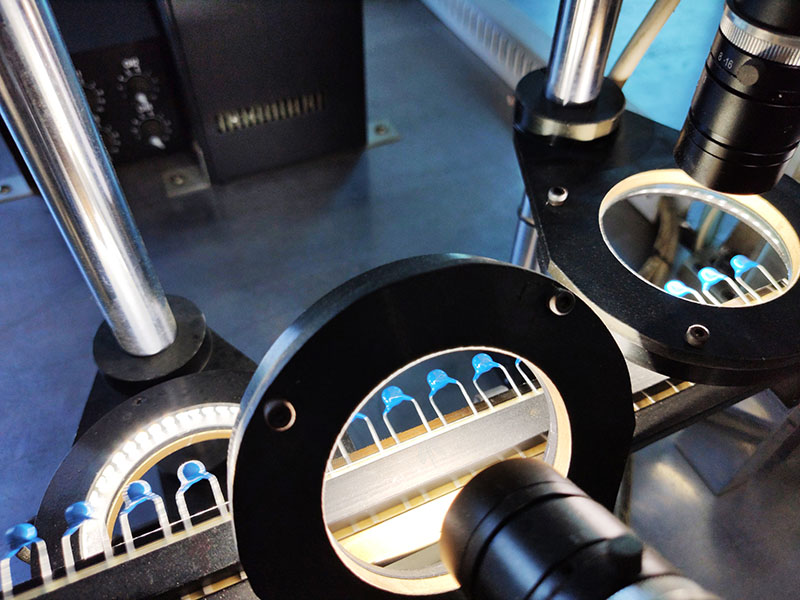

4. Soldering Inspection

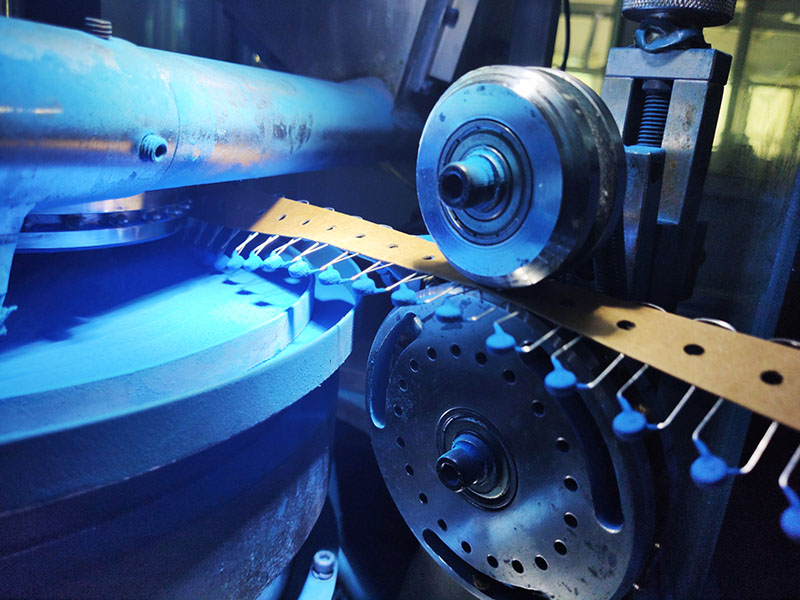

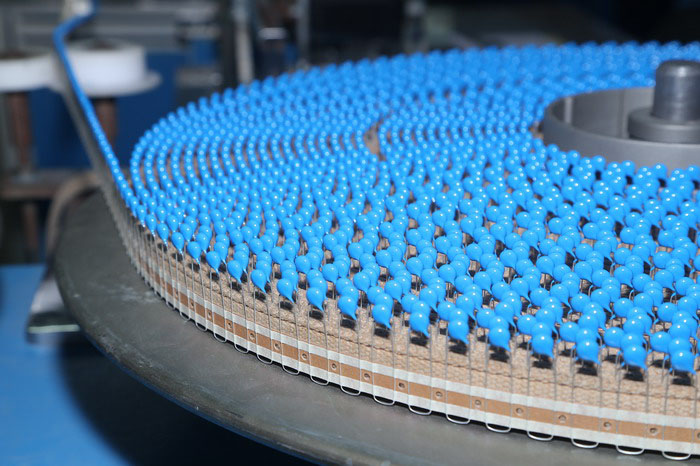

5. Epoxy Resin Coating

6. Baking

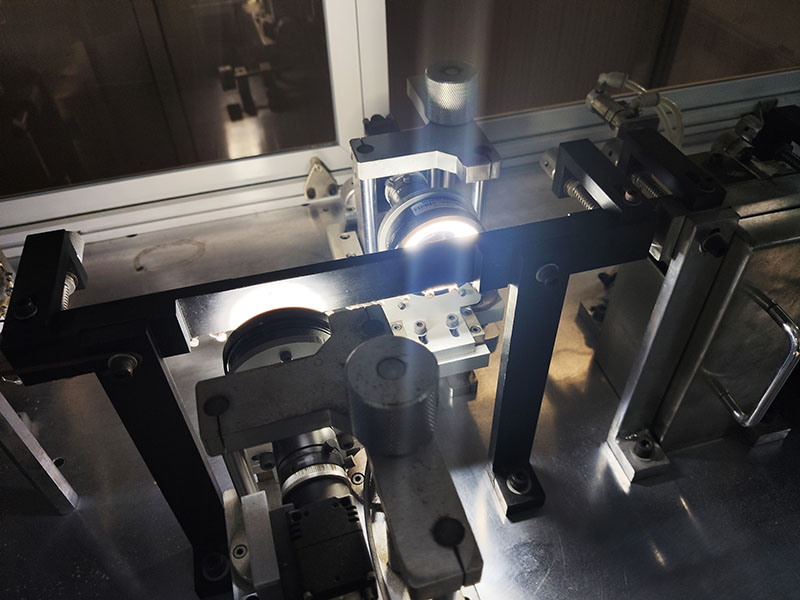

7. Laser Printing

8. Electrical Performance Test

9. Appearance Inspection

10. Lead Cutting or Pulling Out

11. FQC and Packing

Certifications

Certification

Our factories have passed ISO-9000 and ISO-14000 certification. Our safety capacitors (X2, Y1, Y2, etc.) and varistors have passed CQC, VDE, CUL, KC, ENEC and CB certifications. All our capacitors are eco-friendly and comply with the EU ROHS directive and REACH regulations.

About Us

Our company has strong technical force and engineers with rich experience in ceramic capacitor production. Relying on our strong talents, we can assist customers in capacitor selection and provide complete technical information including inspection reports, test data, etc., and can provide capacitor failure analysis and other services.

1) The quantity of capacitors in each plastic bag is 1000 PCS. Internal label and ROHS qualification label.

2) The quantity of each small box is 10k-30k. 1K is a bag. It depends on the product volume.

3) Each large box can hold two small boxes.

1: What is the difference between safety capacitors and ordinary capacitors?

The discharge of safety capacitors is different from that of ordinary capacitors. Ordinary capacitors will retain the charge for a long time after the external power supply is disconnected. Electric shock may occur if one touches an ordinary capacitor by hand, while there isn’t such problem with safety capacitors.

For safety and Electro Magnetic Compatibility (EMC considerations), it is generally recommended to add safety capacitors to the power inlet. At the input end of the AC power supply, it is generally necessary to add 3 safety capacitors to suppress EMI conduction interference. They are used in the power supply filter to filter the power supply.

2: What is a safety capacitor?

Safety capacitors are used in such occasions that after the capacitor fails: it will not cause electric shock and will not endanger personal safety. It includes X capacitors and Y capacitors. The x capacitor is the capacitor connected between the two lines of the power line (LN), and metal film capacitors are generally used; the Y capacitor is the capacitor connected between the two lines of the power line and the ground (LE, NE), and usually appears in pairs. Due to the limitation of leakage current, the Y capacitor value cannot be too large. Generally, the X capacitor is uF and the Y capacitor is nF. The X capacitor suppresses differential mode interference, and the Y capacitor suppresses common mode interference.

3: Why are some capacitors called safety capacitors?

The “safety” in safety capacitors does not refer to the capacitor material, but that the capacitor has passed the safety certification; in terms of material, the safety capacitors are mainly CBB capacitors and ceramic capacitors.

4: How many types of safety capacitors are there?

Safety capacitors are divided into X type and Y type.

X capacitors mostly use polyester film capacitors with relatively large ripple currents. This type of capacitor has a relatively large volume, but its allowable instantaneous charging and discharging current is also large, and its internal resistance is correspondingly small.

The capacitance of the Y capacitor must be limited, so as to achieve the purpose of controlling the leakage current flowing through it as well as the impact on the EMC performance of the system under the rated frequency and rated voltage. GJB151 stipulates that the capacitance of Y capacitor should not be greater than 0.1uF.