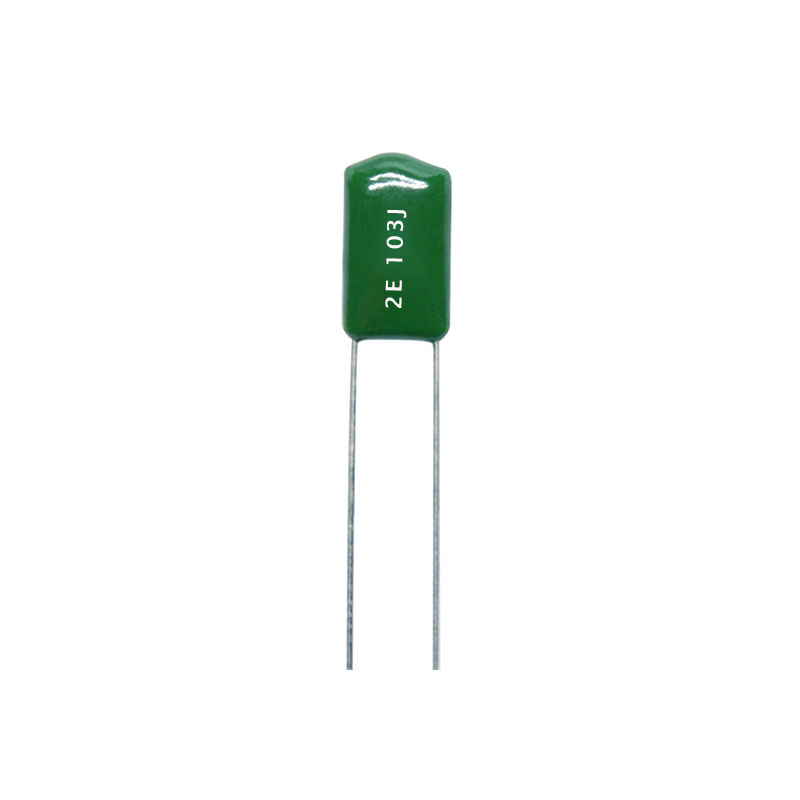

Short Lead Time for 223j 630VDC Cl11 Polyester Film Mylar Capacitor

“Quality initial, Honesty as base, Sincere assistance and mutual profit” is our idea, as a way to produce continuously and pursue the excellence for Short Lead Time for 223j 630VDC Cl11 Polyester Film Mylar Capacitor, Because we stay with this line about 10 years. We got most effective suppliers support on excellent and cost. And we had weed out suppliers with poor high quality. Now several OEM factories cooperated with us too.

“Quality initial, Honesty as base, Sincere assistance and mutual profit” is our idea, as a way to produce continuously and pursue the excellence for China Mylar Capacitor 223j 630VDC and Polyester Capacitor, Based on experienced engineers, all orders for drawing-based or sample-based processing are welcomed. We now have won a good reputation for outstanding customer service among our overseas customers. We’ll continue to try the best to offer you good quality items and the best service. We’re looking forward to serving you.

|

Technical requirements reference Standard |

GB/T 6346 (IEC 60384-11) |

|

Climatic Category |

55/100/21 |

|

Operating Temperature |

-55℃~100℃(+85℃~+105℃:decreasing factor1.25% per℃ for UR) |

|

Rated Voltage |

50V、63V、100V、160V、250V、400V、630V、1000V、1200V |

|

Capacitance Range |

0.001μF~0.47μF |

|

Capacitance Tolerance |

±5%(J) 、±10%(K) |

|

Withstand Voltage |

2.0UR , 5sec |

|

Insulation Resistance(IR) |

CR≤ 0.1μF, IR≥30000MΩ;CR>0.1μF, IR≥10000MΩ at 100V,20℃,1min |

|

Dissipation Factor (tgδ) |

1% Max , at 1KHz and 20℃ |

Application Scenario

Charger

LED lights

Kettle

Rice cooker

Induction cooker

Power supply

Sweeper

Washing machine

CL11 Film Capacitor Application

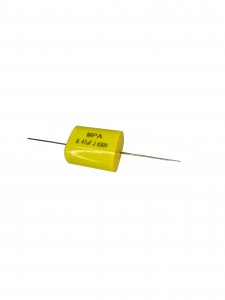

CL11 film capacitors use metal foils as electrodes, which have the characteristics of small size and good insulation performance, and are suitable for DC or pulsating circuits of general household appliances, electronic instruments, and meters.

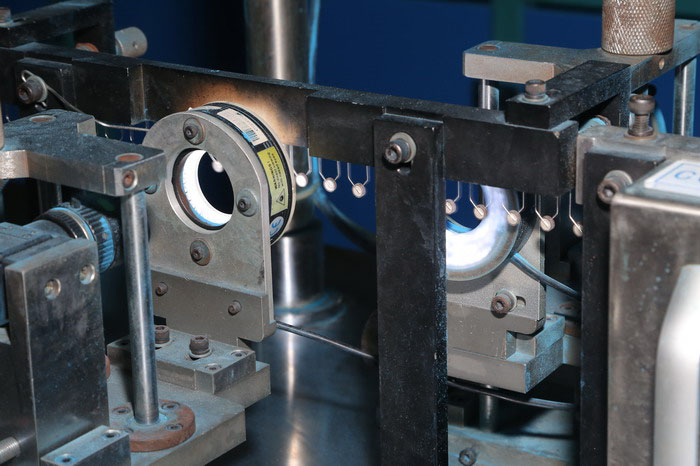

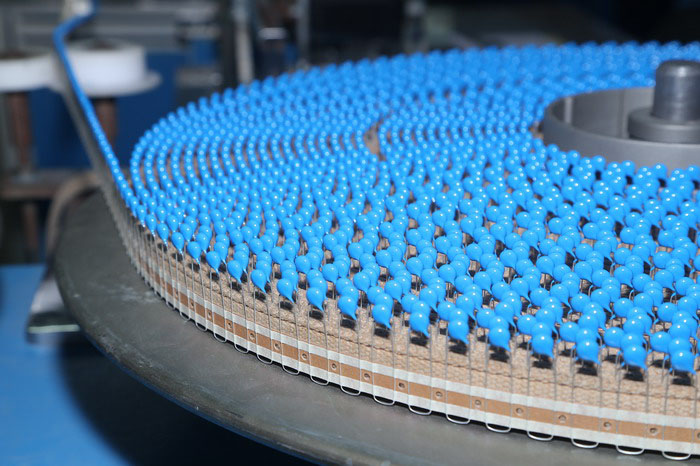

Currently, we not only possess quite a few automated production machines and automated testing machines but also have our own laboratory to test the performance and reliability of our products.

Certifications

Certification

We have passed ISO9001 and ISO14001 management certification. We manufacture products based on the GB standards and IEC standards. Our safety capacitors and varistors have passed CQC, VDE, CUL, KC, ENEC, CB and other authoritative certifications. All of our electronic components comply with ROHS, REACHSVHC, halogen and other environmental protection directives as well as EU environmental protection requirements.

About Us

We Dongguan Zhixu Electronic Co., Ltd. (also JYH HSU (JEC)) have devoted to the R&D, production and marketing of electronic components since 1988. Our main products: ceramic capacitors, EMI suppression capacitors (X2, Y1, Y2), film capacitors (CBB series, CL series, etc), varistors (surge absorber) and thermistors.

Plastic bag is the minimum packing. The quantity can be 100, 200, 300, 500 or 1000PCS. The label of the RoHS includes the product name, specification, quantity, lot No, manufacture date etc.

One inner box has N PCS bags

Inner box size (L*W*H)=23*30*30cm

Marking for RoHS AND SVHC

“Quality initial, honesty as base, sincere assistance and mutual profit” is our idea, as a way to produce continuously and pursue the excellence for Short Lead for 223j 630VDC Cl11 Polyester Film Mylar Capacitor, Because we stay with this line about 30 years. We got most effective suppliers support on excellent and cost. And we had weed out suppliers with poor quality. Now several OEM factories cooperated with us too.

Short Lead Time for China Mylar Capacitor 223j 630VDC and Polyester Capacitor, Based on experienced engineers, all orders for drawing-based or sample-based processing are welcomed. We now have won a good reputation for outstanding customer service among our overseas customers. We’ll continue to try the best to offer you good quality items and the best service. We’re looking forward to serving you.

1. How long can film capacitors be stored?

Film capacitors have a “shelf life”. After the “shelf life”, the performance of film capacitors will decline. Applying “expired” capacitors to electronic products may cause accidents. Therefore, capacitors should be used within the warranty period.

Film capacitors have the best performance within one year after production due to materials and characteristics.

Reminder: It’s not that the film capacitor can only be used for one year, but that the composition of the film capacitor may change after the capacitor has been produced over a year, and the performance will decrease after a long storage time.

2. What should be paid attention to when storing film capacitors?

The temperature and humidity of the environment where the film capacitors are stored should not be too high. Too high temperature will reduce the capacity of the film capacitor, and high humidity will reduce its service life. All electronic components and electronic equipment are more or less affected by temperature and humidity, so be careful. At the same time, keep the storage area ventilated, keep it dry and not too humid.